Maintenance and Change Out

IGS provide a complete range of kettle and furnace services for upgrade, maintenance and repairs of your plant and equipment.

IGS provide a complete range of kettle and furnace services for upgrade, maintenance and repairs of your plant and equipment.

We use the most comprehensive ultrasonic kettle testing unit available to the industry. The kettle testing unit collects data that allows forward planning for security of your operations. The unit allows testing at temps up to 550°c. Tests are performed in an 8 hour period and production can recommence immediately.

Our change out service includes supervision of pump out including molten metal holding vessels, to repairs, maintenance, and recommissioning of all systems followed by remelt out supervision.

***For the further details and/or to receive a product brochure, please click here.

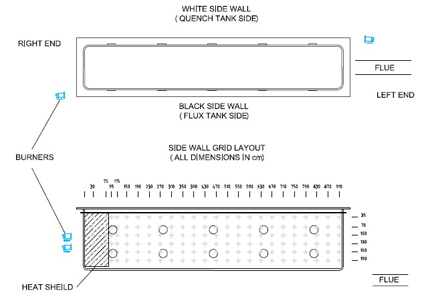

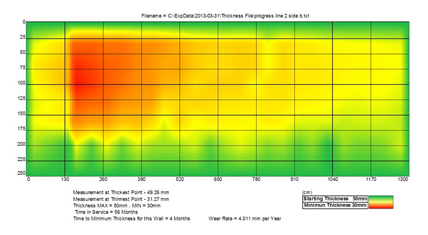

IGS use the most comprehensive ultrasonic kettle testing available to the galvanizing industry for wall thickness testing in molten zinc. The ultrasonic kettle testing device is a specialised ultrasonic probe that allows testing at temperatures up to 550°c. Typically tests are performed in an 8 hour period and production can recommence immediately after testing.

IGS use the most comprehensive ultrasonic kettle testing available to the galvanizing industry for wall thickness testing in molten zinc. The ultrasonic kettle testing device is a specialised ultrasonic probe that allows testing at temperatures up to 550°c. Typically tests are performed in an 8 hour period and production can recommence immediately after testing.

***For the further details and/or to receive a product brochure, please

***For the further details and/or to receive a product brochure, please

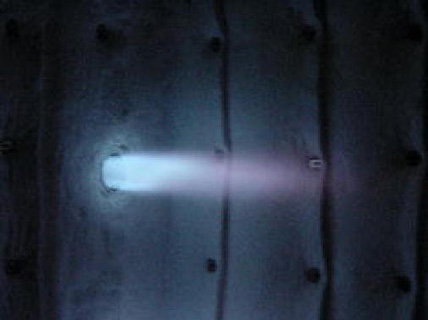

IGS provide inspection and tuning services for all furnace systems. Our inspection and tuning services are designed to ensure correct function and efficient working order of your furnace system. Our inspection checklist covers all aspects from support structure strain inspection through to flue gas analysis.

IGS provide inspection and tuning services for all furnace systems. Our inspection and tuning services are designed to ensure correct function and efficient working order of your furnace system. Our inspection checklist covers all aspects from support structure strain inspection through to flue gas analysis.